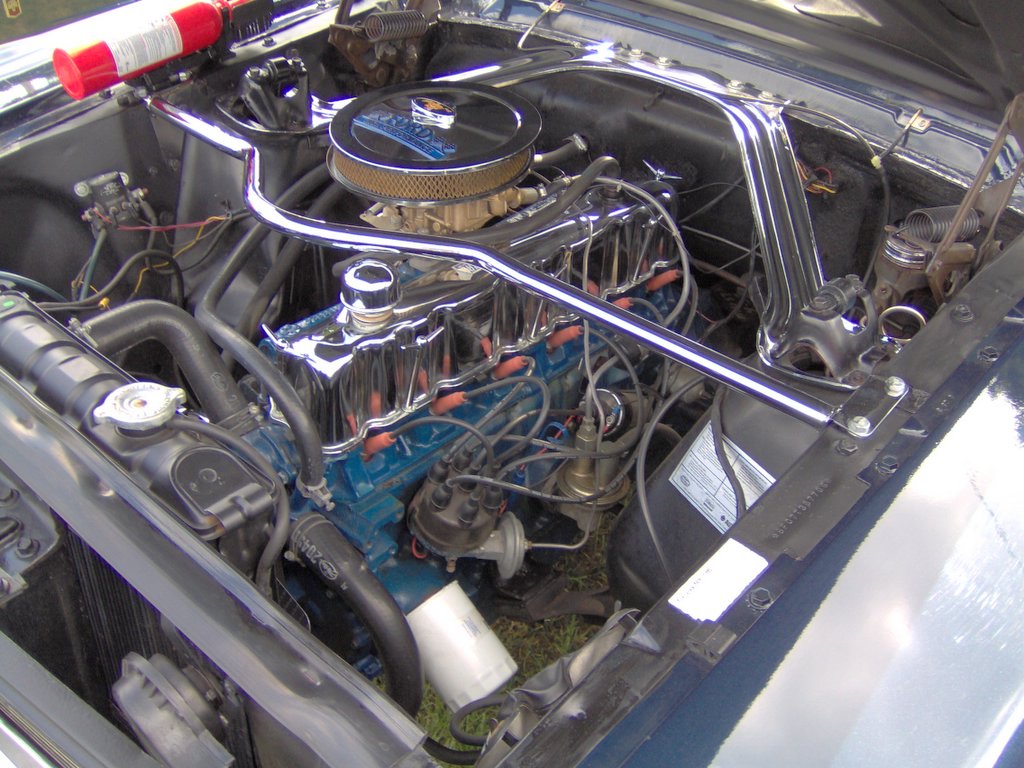

1970 Mustang Engine Information – Thriftpower Inline 6 (200 cubic inch)

The 200 cubic inch engine was used in Mustangs from 1965 -1970. It was an inline 6 cylinder engine with the block and valve covers painted blue. The exhaust was a single exhaust pipe with a single inlet/outlet transverse mounted muffler behind the axle and in front of the gas tank.

Engine Basics

| Year |

1970 |

| Cylinders |

6 |

| Displacement |

200 cu / 3.3 liter |

| Power (hp) |

120 hp |

| Compression |

8.8/1 |

| Bore x Stroke |

3.680 x 3.130 |

Engine Specs (200 cid inline 6)

| Spark Plugs |

BF 82 set gap to 0.034 |

| Oil filter |

|

| Gas Filter |

|

| Air Filter |

|

| PCV |

|

| Oil |

4.5 quarts of 10W30 or 10W40 |

| Oil Pressure |

35 – 55 PSI |

| Points |

Gap and Dwell at xxx RPM |

| Timing |

6 Degrees BTDC Manual & 12 Degrees BTDC Automatic |

| Valve adjustment and size |

Cold: 1.642-1.657 Intake, Hot: 1.381-1.396 Exhaust |

| Valve arrangement |

E I I E I E E I E I I E Front to rear |

| Manifold Vacuum |

17 inches at idle |

| Warm Idle Manual Trans |

575 – 600 RPM |

| Warm Idle Auto Trans |

500 – 525 RPM |

| Carburetor CFM |

|

| Bore and stroke |

3.680 X 3.126 |

| Compression |

9.2:1 (155 – 195 psi @ cranking speed) |

| Combustion chamber |

49.3 – 50.5 cc |

| HP and Torque |

120 hp at 4400 RPM and 190 ft/lbs torque at 2400 RPM |

| Taxable HP |

32.5 |

| Distributor Rotation |

Counter-Clockwise |

| Firing order |

1 – 5 – 3 – 6 – 2 – 4 |

|

|

Engine Torque Specifications

All torque specifications provided in this table are those recommended by FORD. If you use special bolts, follow the torque specifications provided by the manufacturer. I recommend that you use the 3 step torque technique where you torque down the bolts in three equal steps. Once you have reached the maximum recommended torque setting, go around one more time. Do not torque in a circular pattern. Always torque cross to cross.

No Subscription? You’re missing out

Get immediate ad-free access to all our premium content.

Get Started